Eddy Current / Electromagnetic Testing

Eddy currents are created through a process called electromagnetic induction. When alternating current is applied to the conductor, such as copper wire, a magnetic field develops in and around the conductor. This magnetic field expands as the alternating current rises to maximum and collapses as the current is reduced to zero. If another electrical conductor is brought into the close proximity to this changing magnetic field, current will be induced in this second conductor. Eddy currents are induced electrical currents that flow in a circular path. They get their name from "eddies" that are formed when a liquid or gas flows in a circular path around obstacles when conditions are right.

|

Step 1 :In order to generate eddy currents a "probe" is used. Inside the probeis a length of electrical conductor which is formed into a coil. |

|

Step 2: Alternating current is allowed to flowin the coil at a frequency chosen by the technician for the type of test involved. |

|

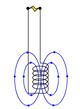

Step 3: A dynamic expanding collapsingmagnetic fieldforms in & aroundthe coil as the alternating current flowsthrough the coil. |

|

Step 4: When an electrically conductive materialis placed in the coil's dynamic magnetic field electromagnetic induction will occur & Eddy currents will be inducedint the material. |

|

Step 5: Eddy currents flowing in the material will generate their own "secondary" magnetic field which will oppose the coils "primary" field. This entire electromagnetic induction process to produce eddy currentsmay occur from several hundreds to several million times each second depending upon inspection frequency. |

|

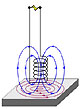

Step 6: When a flaw is introduced to the conductive materia, the Eddy currents are disrupted. |

Main Uses

Eddy Currents can be used for:

- Crack Detection.

- Material Thickness Measurements.

- Coating Thickness Measurements.

- Conductivity Measurements For:

- Material Identification.

- Heat Damage Detection.

- Case Depth Determination.

- Heat Treatment Monitoring.

Main Advantages

One of the major advantages of eddy current as an NDT tool is the variety of inspections and measurements that can be performed.

Some of the advantages of eddy current inspection include:

- Sensitive to small cracks and other defects.

- Detects surface and near surface defects.

- Inspection gives immediate results.

- Equipment is very portable.

- Method can be used for much more than flaw detection.

- Minimum part preparation is required.

- Test probe does not need to contact the part.

- Inspects complex shapes and sizes of conductive materials.

Disadvantages

- Only conductive materials can be inspected.

- Surface must be accessible to the probe.

- Skill and training required is more extensive than other techniques.

- Surface finish and and roughness may interfere.

- Reference standards needed for setup.

- Depth of penetration is limited.

- Flaws such as delaminations that lie parallel to the probe coil winding and probe scan direction are undetectable.